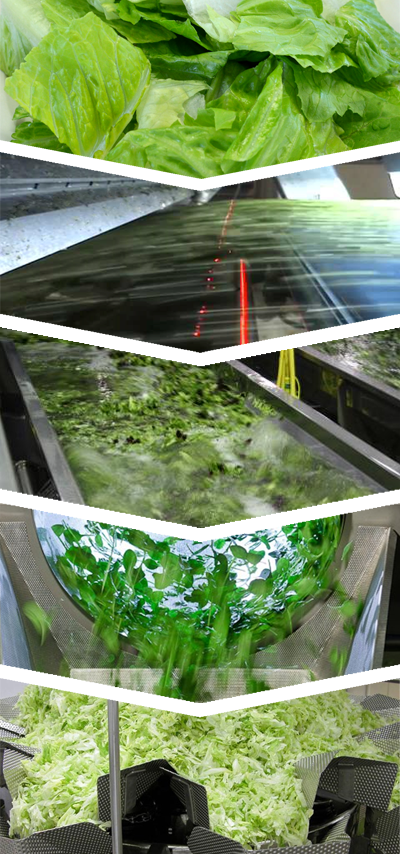

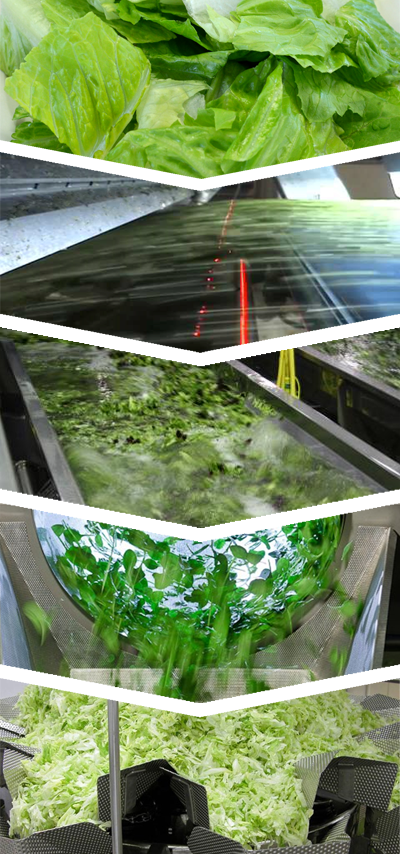

On-Farm Processing

Our world-class processing facility incorporates advanced machinery from start to finish, including advanced optical sorting, a chlorinated double-wash system and sophisticated drying technology. After the raw product is prepared for cutting at the front of our line every stage of the process is fully automated and there is no need for human handling until the product emerges from the end of the line in its sealed, ready-to-eat package. This enables us to produce the freshest, safest and most consistent product to our customers, year round.

Key areas of our processing line which combine to give a superior finished product include:

Cutting

We use the best cutting machinery and technology available to achieve a uniform cut with minimum product damage. Every cut surface provides a point for the product to start breaking down, so we make sure the cut is clean and in the best condition possible

Multi-Spectrum Sorting

Each piece of product is inspected by multi-spectrum laser imaging, full colour imaging and infrared imaging on state of the art, high speed sorting equipment. Any product defects, contaminants or foreign objects are removed by the sophisticated sorting technology leaving only fresh, defect free product to continue through the processing line

Washing

Two separate stages of Jacuzzi washing gently submerges and washes all product in chilled, sanitised water leaving the produce fresh, clean and ready-to-eat. We carefully monitor and control this critical point of the process and use chlorinated water to remove pathogens and naturally occurring bacteria

Drying

State of the art dryers gently remove any excess moisture from the product leaving it ready for packing. This is a crucial step in the process and our high capacity, heavy duty dryers leave the perfect residual moisture in the product - allowing product to stay fresh and appealing for longer

Packing

Automated weighing and bagging systems pack the finished product into a hygienic, sealed pack using specially developed films matched to the product’s physiology. These films control the atmosphere around the product, letting Oxygen in and Carbon Dioxide out at carefully selected rates. This maximises the shelf life of delicate products, keeping fresh-cut produce in the best possible condition until it is used.