Processing Philosophy

At Story Fresh, we are dedicated to providing the best quality product in the safest possible way - year round. We continually improve our processing abilities and in the last few years we’ve invested heavily in our processing line which is comprised of leading-edge processing equipment. Our machinery is sourced from all over the world including Europe, USA and Australia. We then combine advanced machinery, in-house expertise developed from over 20 years of processing and high quality raw product to deliver a platform for consistent, safe, quality fresh-cut produce.One of the core philosophies to the processing of our delicate products is speed. When a lettuce is cut from the field it is still living and respiring - using oxygen and producing carbon dioxide. So the race is on to get the raw product cut, inspected, washed, dried and into the finished bag where we can control the freshly processed products respiration and give you the maximum shelf life.

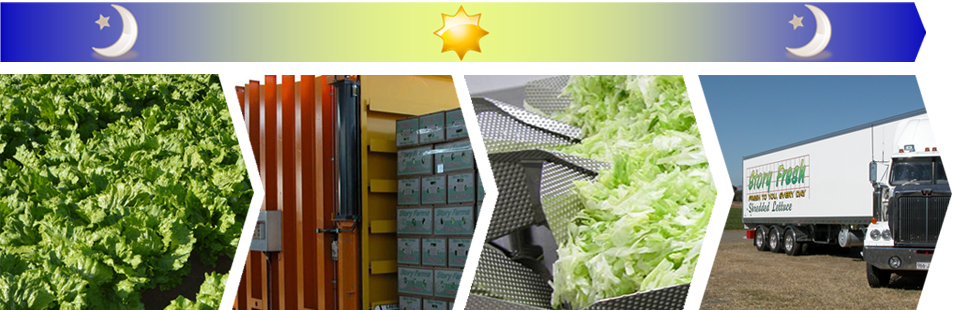

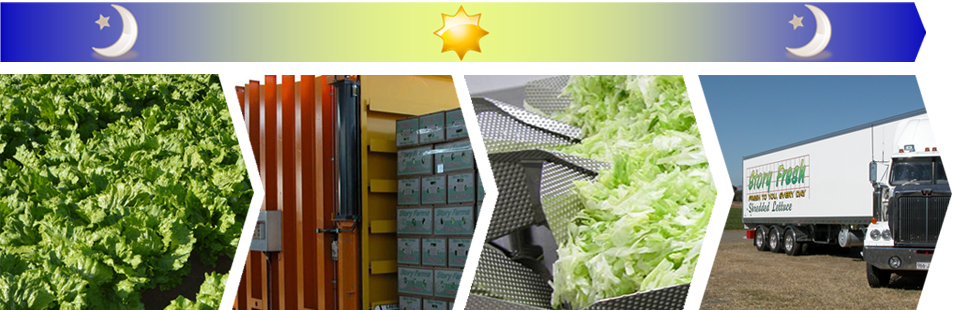

On The Day Of Harvest We Will

Decades of experience, innovation and investment kick in on the day the product is harvested - all to get the product as quickly as possible from the field to you. On the day the produce is harvested we will:

CutOn the day the field grown produce is ready, it is carefully trimmed and harvested | CoolAll product is vacuum cooled immediately after cutting, removing heat from the product and maximising its life | ProcessAfter cooling, the product is cut, sorted, double washed, dried and packed in our on-farm processing facility | DeliverYour fresh, ready-to-eat produce is on its way to you, just hours after being harvested |